Introduction

Chemical provide firms for oil and gasoline nicely drilling rigs are among the many chemical distribution facilities which have obtained much less consideration and examine. These firms are primarily lively in oil-producing international locations. Conducting an entire examine of the danger potential of chemical substances for workers and different people who find themselves uncovered to its exercise is taken into account analysis innovation. Therefore, the well being danger brought on by publicity to those substances has been investigated within the current examine utilizing COSHH, SQRA, and CHEM-SAM strategies.

Materials and strategies

MI Services, a chemical provide firm for drilling rigs, is situated within the oil-rich areas of southwestern Iran. This firm has three chemical warehouses used within the drilling trade with a complete space of 80,000 m2. On common, 40 tons of chemical compounds enter and go away warehouses day by day. The loading and unloading technique of 500 kg and 50 kg packs is carried out by forklifts and drums by warehouse employees manually, respectively. A complete of 38 warehouse employees are always in direct contact with these substances.

Health danger evaluation utilizing COSHH methodology

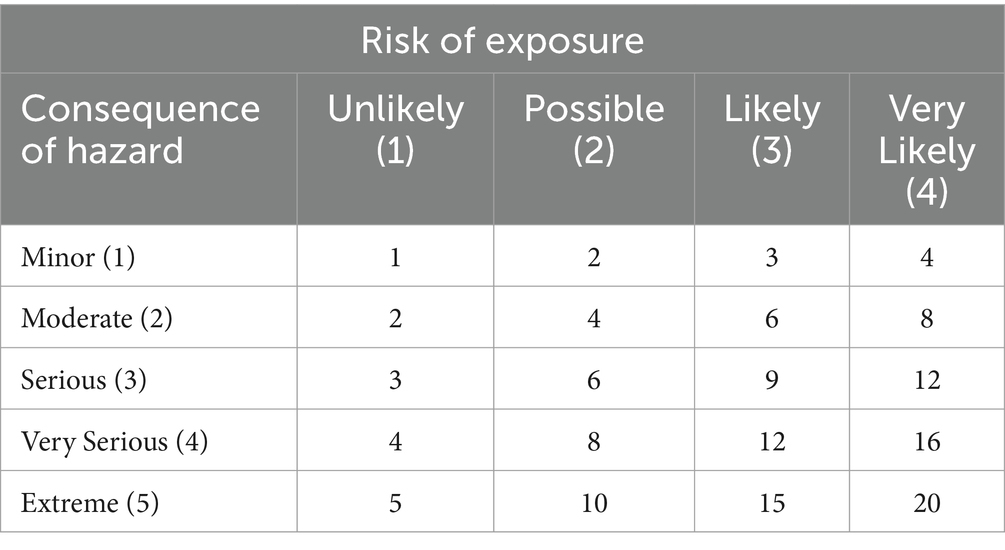

The directions of the Organization for Control of Substances Hazardous to Health for chemical compounds have been categorized within the two parameters of consequence and publicity chance in the usual matrix and questionnaire, as very low, low, medium, excessive, and really excessive danger (44). The publicity chance was calculated by knowledgeable observations of the work setting, related measurements, and by contemplating parameters equivalent to the sort and quantity of chemical compounds utilized in chemical warehouses. The evaluation matrix of the consequence severity and the publicity chance within the COSHH methodology is introduced in Table 1 and the danger classification based mostly on the danger precedence quantity is introduced in Table 2.

Table 1. Matrix of severity and danger of publicity to chemical compounds in COSHH methodology (41).

Table 2. Classification of well being dangers in COSHH methodology based mostly on precedence quantity (41).

Health danger evaluation utilizing the SQRA methodology

There are two necessary elements on this methodology: Hazard price (HR) and publicity price (ER). After figuring out the chemical uncooked substances within the firm’s warehouses, HR was decided utilizing data on acute toxicity values, LD50 and LC50, or by way of the poisonous results of chemical compounds outlined in tables. The second issue is the publicity price (ER), which is obtained utilizing the next two methods:

E

=

F

×

D

×

M

W

(1)

Where; E: Weekly publicity (ppm or mg/m3), F: Frequency of exposures per week, M: Exposure stage (ppm or mg/m3), W: Average weekly working hours (40 h), D: Average publicity time in hours.

R

=

E

1

×

E

2

×

…

.

×

E

n

1

2

(2)

Where n is the variety of publicity indices used and EI is the publicity index.

First: Based on precise publicity ranges when air monitoring outcomes can be found. The weighted common weekly publicity is calculated utilizing the Equation 1:

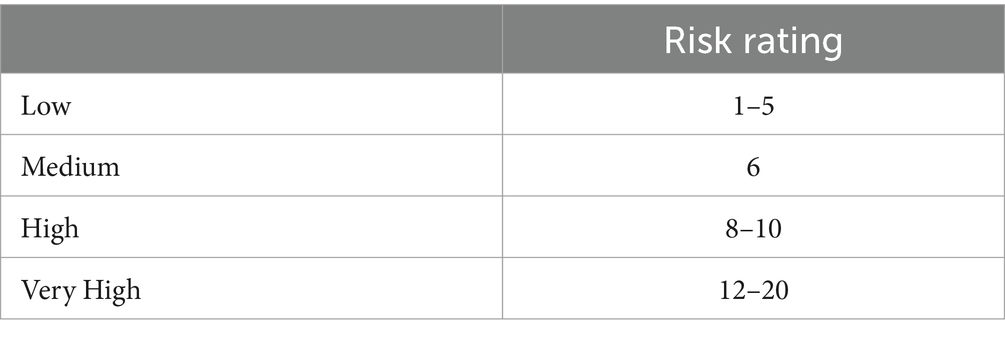

The calculated E is in contrast with the occupational publicity restrict (OEL) after which the publicity price is decided in line with Table 3.

When publicity to 2 or extra chemical compounds with related results happens, mixed publicity is considered.

Second: Using ER index: when air monitoring outcomes will not be out there, the publicity diploma will be obtained utilizing the publicity index (EI) and by the Equation 2:

Table 3. Chemical publicity price in SQRA methodology (42).

The EI (publicity index) is decided in line with the publicity elements outlined within the tables. Finally, the hazard price is calculated by calculating ER and HR by way of the Equation 3:

SQRA = (HR × ER)

1

2

(3)

Risk is obtained in 5 ranges: insignificant (0–0.5), low (0.51–1), medium (1–2), excessive (2–3), and really excessive (>3).

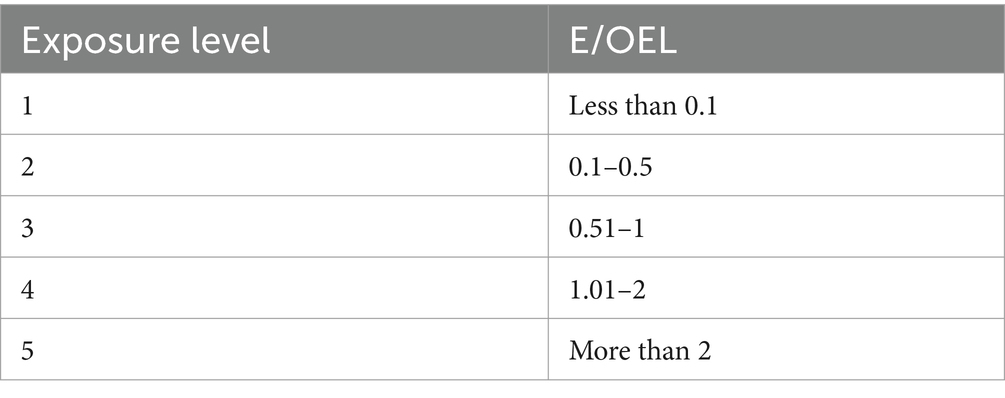

Health danger evaluation utilizing CHEM-SAM methodology

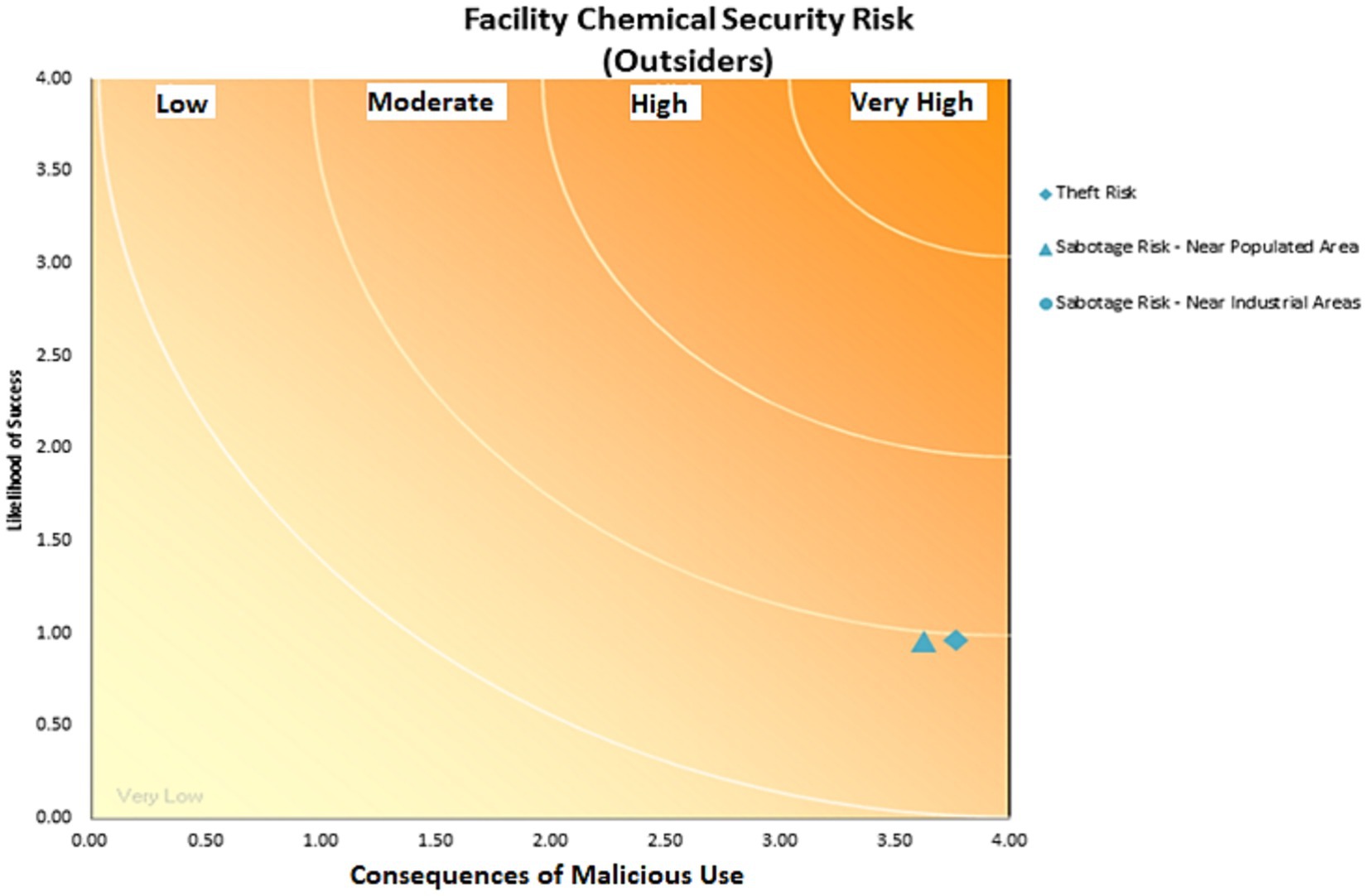

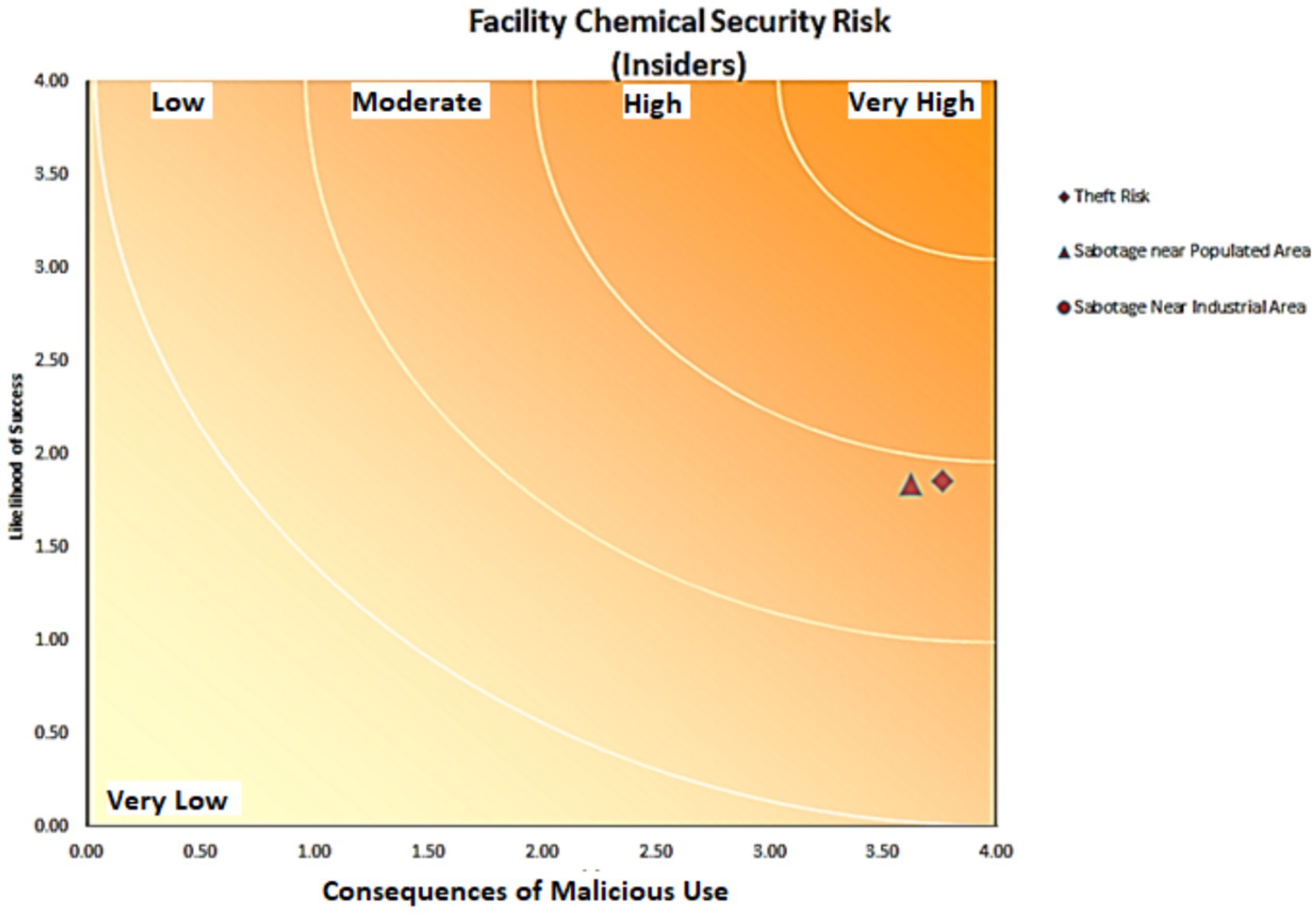

This methodology, which was designed by the International Chemical Threat Reduction Department of Sandia National Laboratories in United States, relies on a number of steps. Defining the doubtless dangerous properties of chemical compounds, calculating the security danger of chemical compounds, and figuring out danger acceptability. This methodology comprises 63 questions on variables such because the storage situations of and substance switch, toxicity, flammability, volatility, bodily kind, route of entry into the physique, sort of publicity, protected packaging situations of the substance, management situations within the desired setting, labeling, management situations exterior the work setting, warning gadgets, coaching to manage situations exterior the work setting, warning substances, substance destruction situations, administration, and planning which are designed in Excel software program. Each variable contains associated questions which are answered based mostly on 4 choices. After answering all of the questions within the Excel software program, the danger stage is decided. This methodology consists of 5 ranges of danger: very low, low, medium, excessive, and really excessive (26) (Figure 1).

Figure 1. Output for assessing the lethality stage of chemical danger (A: Outside the enclosure; B: Inside the enclosure)-2021.

Results

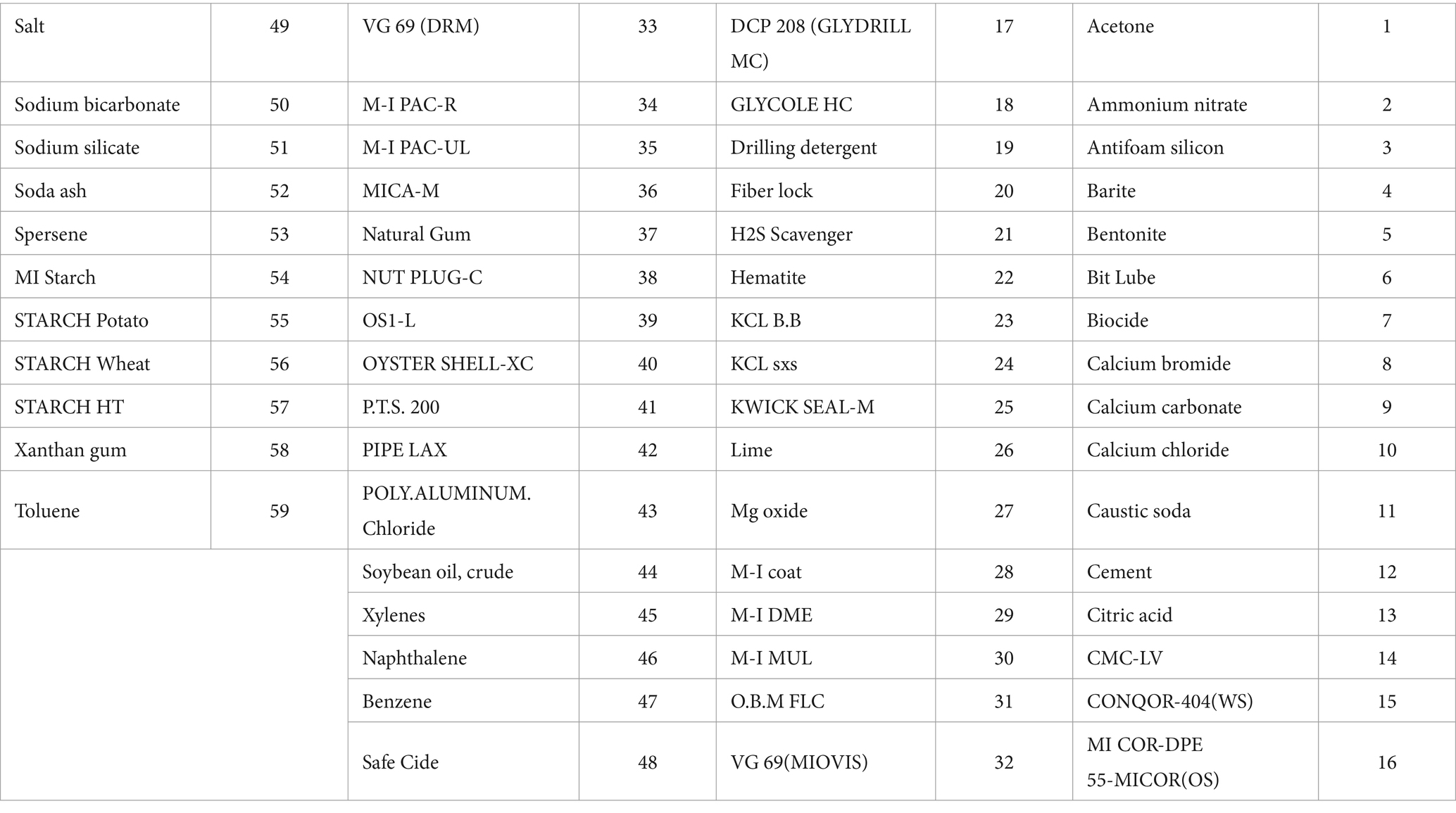

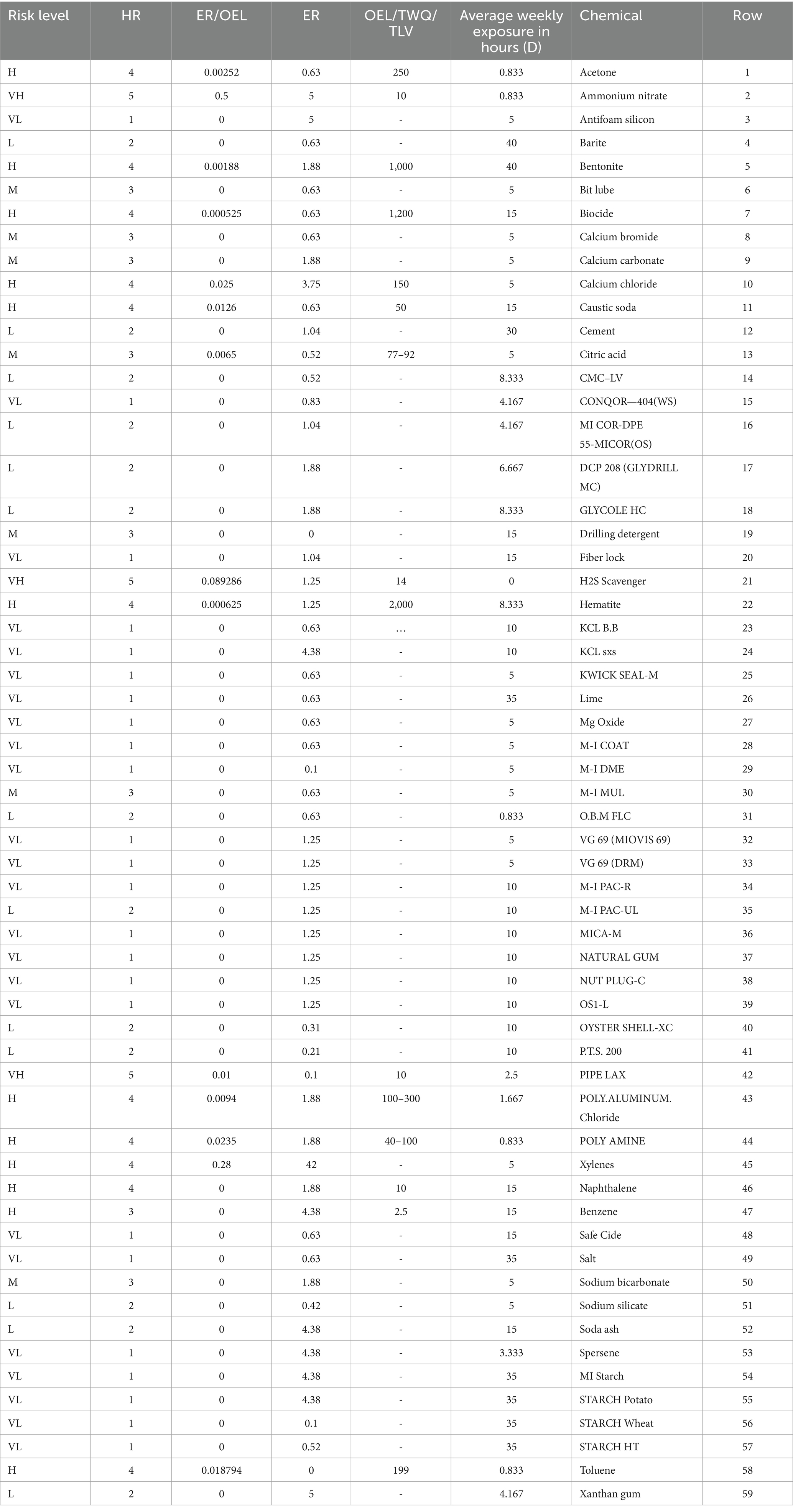

To analyze the well being dangers of MI Services firm’s uncooked substances, a listing of chemical compounds utilized in warehouses was ready. This checklist comprises 59 chemical compounds (Table 4).

Table 4. List of chemical compounds recognized within the drilling rig chemical provide company-2021.

Results of the well being danger evaluation utilizing of COSHH methodology

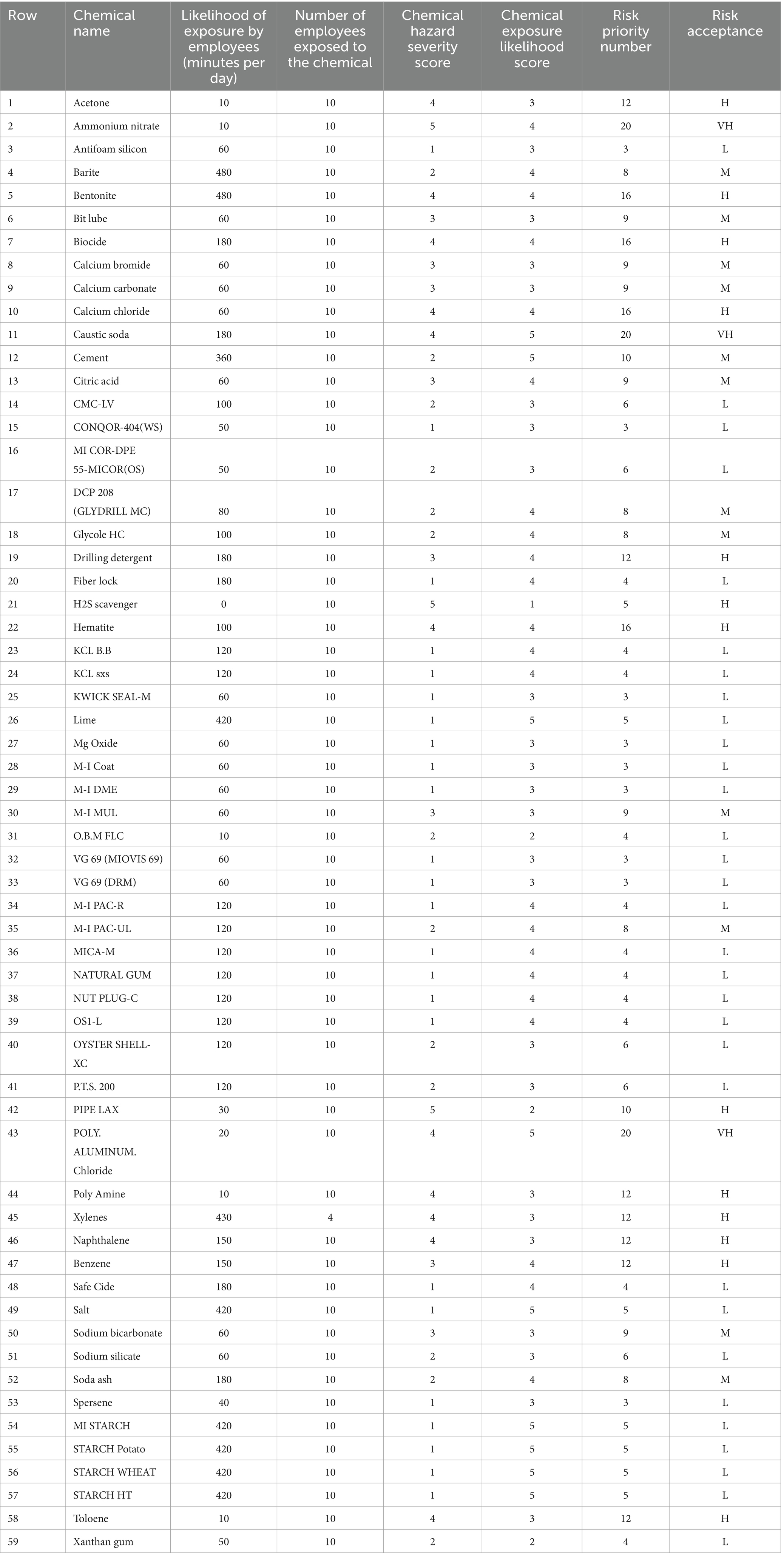

The danger precedence on this methodology is the product of two danger severity parts (the severity of the chemical danger) and the danger chance (the extent of chemical publicity). The severity part is assessed into 5 ranges: low, medium, critical, very critical, and extreme. The chance part can also be categorized into 4 ranges: unlikely, doable, possible, and extremely possible. Part of the outcomes of the COSHH-based well being danger evaluation of chemical compounds are introduced in Table 5.

Table 5. Results of chemical danger evaluation of chemical compounds in COSHH methodology within the drilling rig chemical provide company-2021.

The outcomes of the COSHH evaluation confirmed that 31 chemical compounds (52.5%) have low danger, 13 chemical compounds (22.03%) have medium danger, 12 chemical compounds (20.3%) have excessive danger and three chemical compounds include Ammonium Nitrate، Caustic Soda, and Poly. Aluminum.Chloride (5.08 %) has a really excessive danger. The highest danger ranges have been associated to ammonium nitrate and benzene with a precedence variety of 20. The danger precedence quantity for supplies together with cement, Poly Amine, Pipe Lax, and Hematite has additionally been at a excessive stage.

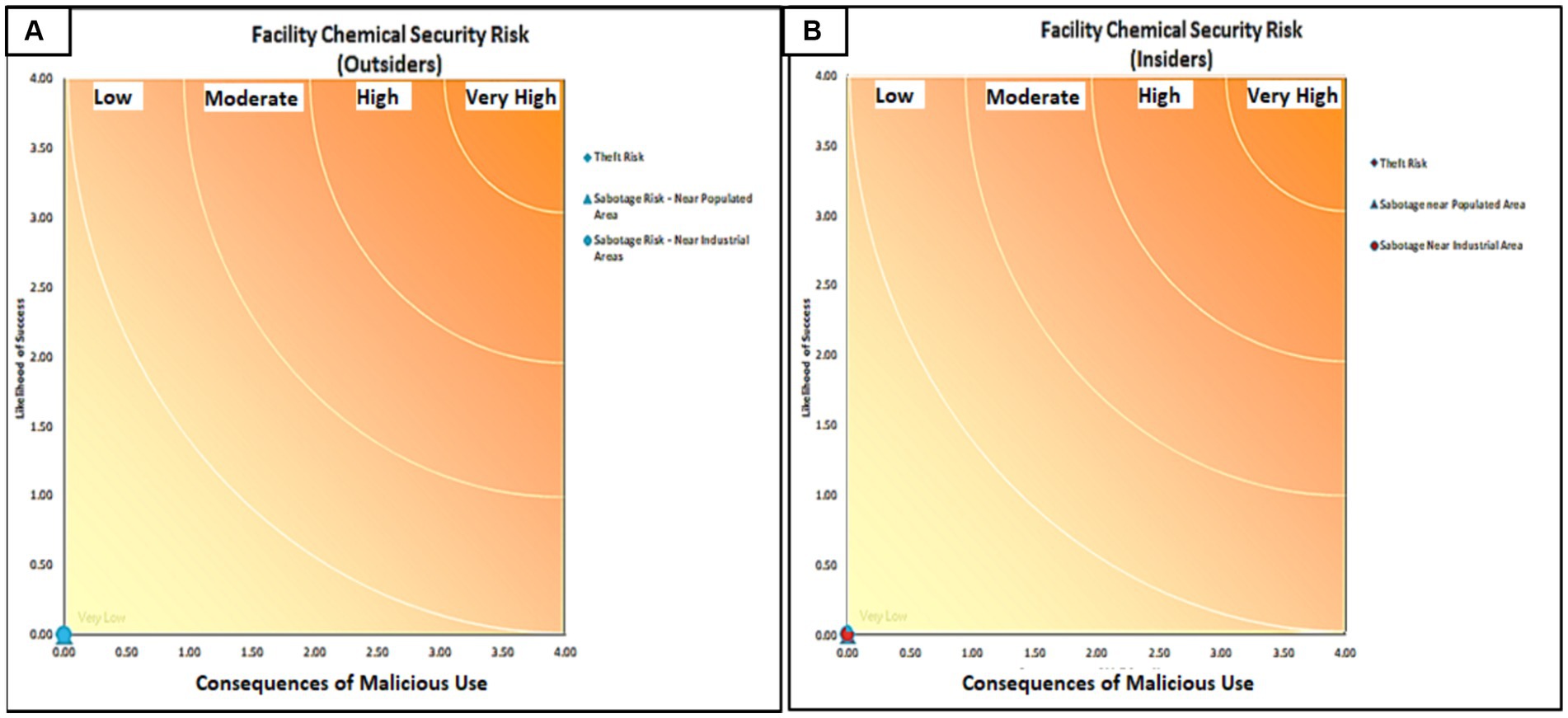

Results of the well being danger evaluation utilizing CHEM-SAM methodology

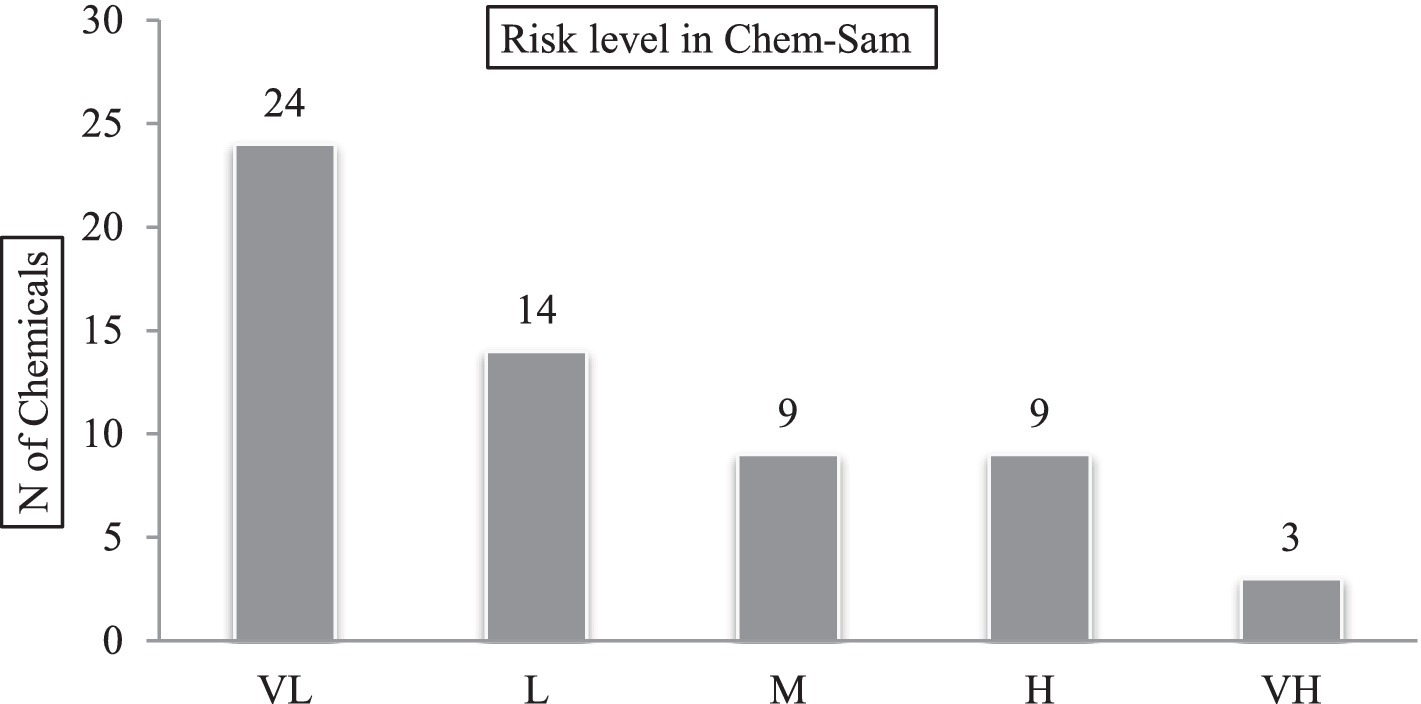

The CHEM-SAM-based well being danger evaluation depends on the character of the information and the administration of chemical compounds. In this evaluation methodology, 10 parts have been evaluated individually for every chemical and 53 parts have been evaluated basically for all chemical compounds. The evaluation output on this methodology consists of 5 ranges of very low, low, medium, excessive, and really excessive danger for workers and other people exterior the group. The outcomes of the well being danger evaluation of the studied chemical compounds are proven within the graphs in Figure 2.

Figure 2. Classification of chemical compounds based mostly on a few of the parts studied within the CHEM-SAM method-2021. (A) Stability, (B) Flammability, (C) Allergy in case of inhalation, (D) Fatal in case of inhalation, (E) Subject to the Law on Prohibition of Chemical Weapons, (F) Fatal in case of swallow.

According to the outcomes, 7 chemical compounds, together with bentonite, calcium chloride, cement, drilling detergents, biocide, hematite, and KCL BB, have excessive stability within the setting (Figure 2A).

A complete of 14 chemical compounds in MI firm’s chemical warehouse are flammable (23.7%) and 45 chemical compounds are non-flammable (76.3%) (Figure 2B). Of the 59 studied chemical compounds, 22 trigger allergic responses (within the case of inhalation 37.3 % of the whole chemical compounds) (Figure 2C). Also, a complete of 23 circumstances (39%) of the chemical compounds utilized in MI Company trigger some type of persistent impact and 18 circumstances (30.5%) of them induce an acute impact. Moreover, seven chemical compounds (11.8%) are secure within the setting. The three substances together with biocide, hydrogen sulfide, and pipe lax (5%) can result in dying if inhaled (Figure 2D). The outcomes of Chem-Sam-based chemical danger evaluation are proven in Figures 3, 4. The outcomes additionally confirmed that no chemical compounds saved within the firm’s warehouse are on the checklist of the Organization for the Proliferation of Chemical Weapons (Figure 2E). A complete of 8 chemical compounds (13.5%) used within the firm’s chemical warehouse, together with acetone, ammonium nitrate, bentonite, biocide, calcium chloride, caustic, pipe lax, and toluene, result in dying if swallowed (Figure 2F). The outcomes present the publicity of staff to harmful chemical compounds, with varied penalties on this Company Supplying Chemicals.

Figure 3. Chemical security danger of kit for folks exterior the drilling rig chemical provide company-2021.

Figure 4. Chemical security danger of kit for folks contained in the drilling rig chemical provide company-2021.

According to the CHEM-SAM methodology, it was discovered that staff are at a medium danger of chemical compounds based mostly on the present administration of chemical compounds within the chemical warehouse of the MI firm (Figure 3) and other people exterior the group are at a low danger (Figure 4). It was additionally discovered {that a} complete of chemical compounds triggered a really low, low, medium, excessive, and really excessive danger in 24 (40.67%), 14 (23.7%), 9 (15.2%), 9 (15.2%) and three circumstances (5%), respectively (Figure 5).

Figure 5. Frequency distribution of chemical danger ranges based mostly on Chem Sam methodology within the drilling rig chemical provide company-2021.

Results of well being danger evaluation utilizing SQRA methodology

The abstract of the outcomes of the well being danger evaluation of chemical compounds used within the MI Company is introduced in Table 6. SQRA consists of two necessary elements: Hazard price (HR) and publicity price (ER). OEL/TWA and TLV indices have been used for the publicity stage. The common minutes of every day publicity have been additionally transformed to hours per week. ER was calculated utilizing Equation 2 and, lastly, the danger precedence of chemical compounds was calculated by multiplying it by the HR.

Table 6. Results of chemical danger evaluation of chemical compounds in SQRA methodology within the drilling rig chemical provide firm—2021.

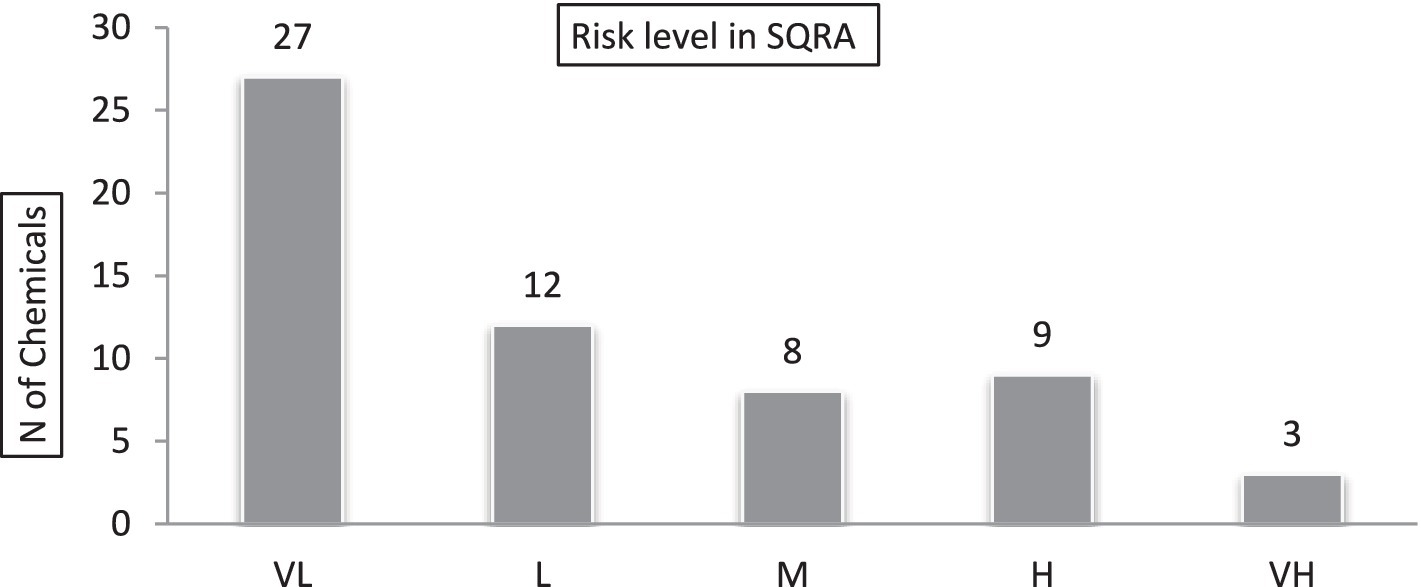

The frequency distribution of the danger of chemical compounds is introduced in Figure 6. These outcomes present that chemical compounds triggered a really low, low, medium, excessive, and really excessive danger in 27 (46%), 12 (20%), 8 (14%), 9 (15%) and three circumstances (5%), respectively (Figure 6). The outcomes of the danger evaluation utilizing the SQRA methodology additionally confirmed the danger of publicity to Ammonium Nitrate, Caustic Soda, and Poly.Aluminum.Chloride compounds are at a really excessive stage.

Chemical danger evaluation strategies are based mostly on indicators, so completely different outcomes will be anticipated. Adaptation of the outcomes is a technique to measure the desirability of any analysis methodology.

Figure 6. Frequency distribution of chemical danger ranges based mostly on SQRA methodology within the drilling rig chemical provide company-2021.

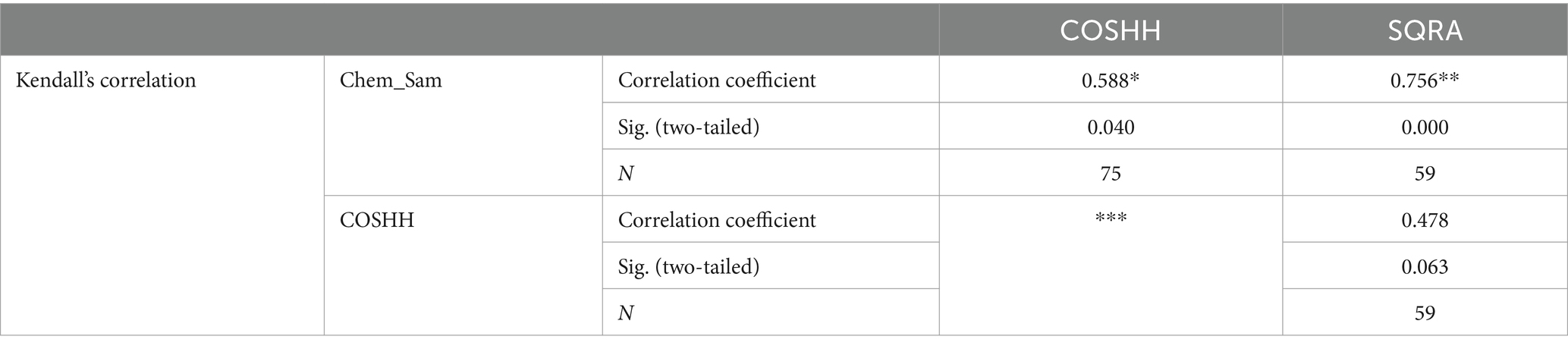

Kendall’s rank correlation coefficient was used to research the correlation between the outcomes of chemical well being danger evaluation strategies (COSHH, CHEM-SAM, and SQRA) utilized in MI Company’s chemical warehouse. These outcomes confirmed a big correlation between the outcomes of SQRA and CHEM-SAM strategies (Sig = 0.756). Kendall’s rank correlation coefficient was calculated to be 0.756 (Table 7). However, there was no vital correlation between the outcomes of the COSHH with the CHEM-SAM and SQRA strategies (p ≥ 0.05), which might be as a result of completely different precedence classification of chemical compounds within the COSHH methodology with the CHEM-SAM and SQRA strategies.

Table 7. Kendall coordination and correlation coefficient for comparability of COSHH, CHEM-SAM, and SQRA strategies—2021.

Discussion

Oil industries, that are among the many course of industries, trigger many dangers and may result in disastrous and irreparable penalties. These industries consist of 4 major traits together with the amount and high quality of vitality, low flexibility, excessive complexity, and excessive vitality (32). Workers working in industrial workplaces, such because the chemical storage space of drilling rigs, are crucial group uncovered to hazardous chemical compounds and their well being ought to be protected. The strategies used within the present analysis are based mostly on the evaluation and evaluation of chemical compounds used within the chemical warehouse of the drilling trade. The outcomes of the analysis confirmed that a few of the 59 major chemical compounds within the chemical warehouse of the drilling rig require particular administration to cut back the extent of well being danger. Considering these outcomes, there’s a comparatively excessive potential for accidents brought on by publicity to chemical compounds in MI and the prevalence of some persistent signs equivalent to respiratory issues and pores and skin allergy symptoms.

Among the substances that may result in allergic pores and skin reactions, cement, calcium chloride, Drilling Detergent, and Caustic Soda will be talked about. Biocide, which is used to eradicate microorganisms in drilling rig environments, comprises chlorine compounds, formaldehyde, ammonium compounds, and sodium hypochlorite (33). The stage of publicity danger to Biocide has been assessed as excessive within the SQRA methodology, with a median weekly publicity of 5 hours for warehouse personnel. The most important consequence of publicity to Biocide is respiratory infections. Ammonium nitrate is one other chemical compound current within the chemical storage for drilling rigs. It is used for circulation management in oil wells. Its results embody respiratory irritation, gastrointestinal injury, and long-term injury to the nervous system (34). The current analysis signifies that the extent of publicity danger to this chemical could be very excessive based mostly on the danger evaluation.

Exposure to benzene, toluene, xylene, and naphthalene within the gasoline part is one other results of the current examine. Benzene has been recognized as a identified carcinogen. Benzene can induce cytogenetic adjustments equivalent to aneuploidy, gene expression alteration (128), DNA methylation (129), and displacement, resulting in the manufacturing of carcinogenic proteins (35). Vital genes might also be focused by way of gene mutation and/or epigenetic alterations. Additionally, toluene and xylene compounds have opposed results on the nervous, respiratory, and immune techniques. At excessive doses of toluene, human motor exercise has been noticed considerably decrease than pre-exposure ranges (36). According to the outcomes of the current examine, the extent of publicity to those compounds for warehouse and laboratory workers was discovered to be excessive.

The dangerous elements within the office have been measured twice a yr. Therefore, contemplating the character of the group’s exercise and excessive publicity to chemical compounds, it’s endorsed that along with conducting this course of each month, tools for steady testing of hazardous substances and their focus within the setting ought to be ready by the corporate. Also, a part of the poisonous and unsafe emissions from chemical compounds equivalent to acids, polyamine, ammonium nitrate, and pipe lax are brought on by leakage from packaging and drums. The poor packaging high quality of chemical compounds typically results in leakage and a few accidents. Increasing the packaging inspection and packaging high quality management of drugs coming into the chemical warehouses of drilling rigs is a suggestion that may forestall some injury. Liu et al. (37) have really useful the labeling of chemical compounds with flammability and reactivity traits and separate storage. Other causes of accidents embody human errors through the transportation of chemical compounds by hand or forklift that requires the event of a response plan in emergencies. Traffic in chemical warehouses (open and remoted warehouses) have to be in full compliance with security requirements. The use of gloves, particular coveralls, protecting glasses, and masks for the warehouse staff when working with chemical compounds and dealing with chemical compounds which have respiratory results in an remoted room with a unfavourable strain of two.5 pascals is among the issues steered by Bergkamp and Abelkop (38).

Mechanical air flow within the manufacturing space following the ACGIH commonplace can also be one of many different suggestions associated to the storage of chemical compounds.

Determining work shifts is among the efficient options to stop chemical accidents. Bhusnure et al. (39) talked about short-term work shifts as one of many efficient options for stopping accidents brought on by publicity to chemical compounds. OEL/TWA and TLV requirements are used to find out work shifts. Sharma et al. (40) referred to waste contaminated with chemical compounds (equivalent to napkins, fabric, cotton, and so on.) as one of many elements influencing the chemical contamination of warehouses and laboratories containing chemical compounds, which requires administration. Adjusting the ambient temperature whereas working with some substances equivalent to chloroform reduces its emission within the air.

Conclusion

The outcomes of the current analysis confirmed that the opposed well being results of chemical publicity within the drilling trade are at a worrying stage. The outcomes of chemical publicity danger evaluation utilizing SQRA, CHEM-SAM and COSHH strategies confirmed that there’s a excessive potential for well being penalties from publicity to compounds equivalent to ammonium nitrate, caustic soda and poly-aluminum chloride, benzene, xylene and toluene for There are workers. It is usually recommended that the methods used within the current analysis ought to be utilized in different sectors of those industries and its outcomes ought to be utilized in well being danger administration and management packages.

Data availability assertion

Author contributions

SA: Conceptualization, Writing – authentic draft, Writing – evaluation & enhancing. BL: Investigation, Writing – authentic draft, Writing – evaluation & enhancing. MC: Formal evaluation, Investigation, Writing – authentic draft, Writing – evaluation & enhancing. MK: Data curation, Writing – authentic draft.

Funding

Conflict of curiosity

Publisher’s word

References

1. Zhang, J, Fu, J, Hao, H, Fu, G, Nie, F, and Zhang, W. Root causes of coal mine accidents: traits of security tradition deficiencies based mostly on accident statistics. Process Saf Environ Prot. (2020) 136:78–91. doi: 10.1016/j.psep.2020.01.024

Crossref Full Text | Google Scholar

2. Bragatto, P, and Milazzo, MF. A resilient strategy to the security administration of ageing and obsolescence in oil and chemical industries. Chem Eng Trans. (2019) 74:1369–74. doi: 10.3303/CET1974229

Crossref Full Text | Google Scholar

3. Asfaw, S, Enquselassie, F, Tefera, Y, Gizaw, M, Wakuma, S, and Woldemariam, M. Determinants of persistent respiratory signs amongst pharmaceutical manufacturing unit employees. J Trop Med. (2018) 2018:1–10. doi: 10.1155/2018/3815689

PubMed Abstract | Crossref Full Text | Google Scholar

4. Kavlock, RJ, Bahadori, T, Barton-Maclaren, TS, Gwinn, MR, Rasenberg, M, and Thomas, RS. Accelerating the tempo of chemical danger evaluation. Chem Res Toxicol. (2018) 31:287–90. doi: 10.1021/acs.chemrestox.7b00339

PubMed Abstract | Crossref Full Text | Google Scholar

5. Tabari, MRR, Sabzalipour, S, Peyghambarzadeh, SM, and Jalilzadeh, R. Dispersion of risky natural compounds within the neighborhood of petroleum merchandise storage tanks. Environ Eng Manag J. (2021) 20:145–63.

Google Scholar

6. Hämäläinen, P., Takala, J., and Kiat, T. B. (2017). Global estimates of occupational accidents and work-related sicknesses. World 3-4.

Google Scholar

7. Satiarvand, M, Orak, N, Varshosaz, Okay, Hassan, EM, and Cheraghi, M. Providing a complete strategy to grease nicely blowout danger evaluation. PLoS One. (2023) 18:e0296086. doi: 10.1371/journal.pone.0296086

PubMed Abstract | Crossref Full Text | Google Scholar

8. Zaidi, R, Sedmak, A, Kirin, S, Grbovic, A, Li, W, Vulicevic, LL, et al. Risk evaluation of oil drilling rig welded pipe based mostly on structural integrity and life estimation. Eng Fail Anal. (2020) 112:104508. doi: 10.1016/j.engfailanal.2020.104508

Crossref Full Text | Google Scholar

9. David Ytrehus, J, Taghipour, A, Golchin, A, Saasen, A, and Prakash, B. The impact of various drilling fluids on mechanical friction. J Energy Resour Technol. (2017) 139:034502. doi: 10.1115/1.4035951

Crossref Full Text | Google Scholar

10. Saasen, A., Hoset, H., Rostad, E. J., Fjogstad, A., Aunan, O., Westgård, E., et al. (2001). “Application of ilmenite as weight materials in water based mostly and oil based mostly drilling fluids” in SPE Annual Technical Conference and Exhibition. OnePetro.

Google Scholar

11. Samnejad, M., Gharib Shirangi, M., and Ettehadi, R. (2020). “A digital twin of drilling fluids rheology for real-time rig operations” in Offshore Technology Conference. OnePetro.

Google Scholar

12. Fink, J

. Petroleum Engineer’s Guide to Oil Field Chemicals and Fluids. Gulf Professional Publishing (2021) 115–117.

Google Scholar

13. Masoumi, A, and Yengejeh, RJ. Study of chemical wastes within the Iranian petroleum trade and feasibility of hazardous waste disposal. J Environ Health Sci Eng. (2020) 18:1037–44. doi: 10.1007/s40201-020-00525-5

PubMed Abstract | Crossref Full Text | Google Scholar

14. Sarafraz, P, Varshosaz, Okay, Orak, N, Jaafarzadeh, N, and Aghajari, E. Safety, well being, and environmental danger evaluation of the fragrant outlet of imam Khomeini petrochemical firm utilizing LOPA and fuzzy-LOPA and pollution and management actions utilizing the Bow-tie methodology. Front Public Health. (2023) 11:1251548. doi: 10.3389/fpubh.2023.1251548

PubMed Abstract | Crossref Full Text | Google Scholar

15. Taugbøl, Okay., Sola, B., Forshaw, M., and Fjogstad, A. (2021). “Automatic drilling fluids monitoring” in SPE/IADC International Drilling Conference and Exhibition OnePetro.

Google Scholar

16. Caganova, B, Foltanova, T, Plackova, S, Placha, Okay, Bibza, J, Puchon, E, et al. Caustic results of chemical compounds: danger elements for issues and mortality in acute poisoning. Monatsh Chem Chem Monthly. (2017) 148:497–503. doi: 10.1007/s00706-016-1900-x

Crossref Full Text | Google Scholar

17. Kim, JH, Kim, T, Yoon, H, Jo, A, Lee, D, Kim, P, et al. Health danger evaluation of dermal and inhalation publicity to deodorants in Korea. Sci Total Environ. (2018) 625:1369–79. doi: 10.1016/j.scitotenv.2017.12.282

PubMed Abstract | Crossref Full Text | Google Scholar

18. Ibrahim, A, Ali, MM, Abou-Khalil, NS, and Ali, MF. Evaluation of chemical castration with calcium chloride versus surgical castration in donkeys: testosterone as an endpoint marker. BMC Vet Res. (2016) 12:46–9. doi: 10.1186/s12917-016-0670-3

PubMed Abstract | Crossref Full Text | Google Scholar

19. Raazi Tabari, MR, Sabzalipour, S, Peyghambarzadeh, SM, and Jalilzadeh, R. Vapor lack of risky natural compounds (VOCs) from the delivery port of Abadan petroleum refinery. Pollution. (2020) 6:863–78. doi: 10.22059/ballot.2020.302701.810

Crossref Full Text | Google Scholar

20. Zain, SMSM, Azmi, WNFW, Veloo, Y, and Shaharudin, R. Formaldehyde publicity, well being signs and danger evaluation amongst hospital employees in Malaysia. J Environ Prot. (2019) 10:861–79. doi: 10.4236/jep.2019.106051

Crossref Full Text | Google Scholar

21. Sekhavati, E, and Yengejeh, RJ. Assessment optimization of security and well being dangers utilizing fuzzy TOPSIS method (case examine: development websites within the south of Iran). J Environ Health Sustain Dev. (2021) 6:12–28. doi: 10.18502/jehsd.v6i4.8154

Crossref Full Text | Google Scholar

22. Sui, Y, Ding, R, and Wang, H. A novel strategy for occupational well being and security and setting danger evaluation for nuclear energy plant development venture. J Clean Prod. (2020) 258:120945. doi: 10.1016/j.jclepro.2020.120945

Crossref Full Text | Google Scholar

23. Hayes, AW, Li, R, Hoeng, J, Iskandar, A, Peistch, MC, and Dourson, ML. New approaches to danger evaluation of chemical mixtures. Toxicol Res Appl. (2019) 3:239784731882076. doi: 10.1177/2397847318820768

Crossref Full Text | Google Scholar

24. Garrod, ANI, Evans, PG, and Davy, CW. Risk administration measures for chemical compounds: the “COSHH necessities” strategy. J Expo Sci Environ Epidemiol. (2007) 17:S48–54. doi: 10.1038/sj.jes.7500585

PubMed Abstract | Crossref Full Text | Google Scholar

25. Karimi, A, Jamshidi Slukloei, HR, and Eslamizad, S. Designing SQCRA as a software program to semi-quantitative chemical danger evaluation in office. J Occup Hyg Eng. (2014) 1:47–56.

Google Scholar

26. Jackson, N. B. (2017). Risk evaluation and Chem-SAM (No. SAND2017-0040PE). Sandia National Lab. (SNL-NM), Albuquerque, NM (United States).

Google Scholar

27. Konee, ND, and Kuye, A. Chemical safety in NIGERIA: a CASE examine of chosen upstream oil and gasoline amenities. NSChE J. (2019) 34:49–9.

Google Scholar

28. Tian, F, Zhang, M, Zhou, L, Zou, H, Wang, A, and Hao, M. Qualitative and quantitative variations between frequent occupational well being danger evaluation fashions in typical industries. J Occup Health. (2018) 60:337–47. doi: 10.1539/joh.2018-0039-OA

PubMed Abstract | Crossref Full Text | Google Scholar

29. Lee, EG, Harper, M, Bowen, RB, and Slaven, J. Evaluation of COSHH necessities: methylene chloride, isopropanol, and acetone exposures in a small printing plant. Ann Occup Hyg. (2009) 53:463–74. doi: 10.1093/annhyg/mep023

PubMed Abstract | Crossref Full Text | Google Scholar

30. Karimi Zeverdegani, S, Barakat, S, and Yazdi, M. Validation CHEM-SAM mannequin utilizing SQRA methodology in publicity to poisonous substances in a chemistry analysis lab. J Milit Med. (2017) 19:291–8.

Google Scholar

31. Ferguson, A, Solo-Gabriele, H, and Mena, Okay. Assessment for oil spill chemical compounds: present information, information gaps, and uncertainties addressing human bodily well being danger. Mar Pollut Bull. (2020) 150:110746. doi: 10.1016/j.marpolbul.2019.110746

PubMed Abstract | Crossref Full Text | Google Scholar

32. Lawrence, KG, Niehoff, NM, Keil, AP, Jackson, WB II, Christenbury, Okay, Stewart, PA, et al. Associations between airborne crude oil chemical compounds and symptom-based bronchial asthma. Environ Int. (2022) 167:107433. doi: 10.1016/j.envint.2022.107433

PubMed Abstract | Crossref Full Text | Google Scholar

33. Antia, M, Ezejiofor, AN, Obasi, CN, and Orisakwe, OE. Environmental and public well being results of spent drilling fluid: an up to date systematic evaluation. J Hazard Mater Adv. (2022) 7:100120. doi: 10.1016/j.hazadv.2022.100120

Crossref Full Text | Google Scholar

34. Al-Hajj, S, Dhaini, HR, Mondello, S, Kaafarani, H, Kobeissy, F, and DePalma, RG. Beirut ammonium nitrate blast: evaluation, evaluation, and suggestions. Front Public Health. (2021) 9:657996. doi: 10.3389/fpubh.2021.657996

PubMed Abstract | Crossref Full Text | Google Scholar

35. Chiavarini, M, Rosignoli, P, Sorbara, B, Giacchetta, I, and Fabiani, R. Benzene publicity and lung Cancer danger: a scientific evaluation and meta-analysis of human research. Int J Environ Res Public Health. (2024) 21:205. doi: 10.3390/ijerph21020205

PubMed Abstract | Crossref Full Text | Google Scholar

36. Wang, TS, Bo, SONG, Sun, QH, Lin, YX, Yuan, SUN, Pin, SUN, et al. Occupational well being danger evaluation of benzene, toluene, and xylene in Shanghai. Biomed Environ Sci. (2021) 34:290–8. doi: 10.3967/bes2021.038

PubMed Abstract | Crossref Full Text | Google Scholar

37. Liu, X, Li, J, and Li, X. Study of dynamic danger administration system for flammable and explosive harmful chemical compounds storage space. J Loss Prev Process Ind. (2017) 49:983–8. doi: 10.1016/j.jlp.2017.02.004

Crossref Full Text | Google Scholar

38. Bergkamp, L, and Abelkop, A. Regulation of chemical compounds In: L Emma and EV Jorge, editors. The Oxford Handbook of Comparative Environmental Law (2019) 578–60.

Google Scholar

39. Bhusnure, OG, Dongare, RB, Gholve, SB, and Giram, PS. Chemical hazards and security administration in pharmaceutical trade. J Pharm Res. (2018) 12:357–69.

Google Scholar

40. Sharma, BM, Bečanová, J, Scheringer, M, Sharma, A, Bharat, GK, Whitehead, PG, et al. Health and ecological danger evaluation of rising contaminants (prescribed drugs, private care merchandise, and synthetic sweeteners) in floor and groundwater (ingesting water) within the Ganges River basin, India. Sci Total Environ. (2019) 646:1459–67. doi: 10.1016/j.scitotenv.2018.07.235

PubMed Abstract | Crossref Full Text | Google Scholar

42. Hoseini, LK, Yengejeh, RJ, Rouzbehani, MM, and Sabzalipour, S. Health danger evaluation of risky natural compounds (VOCs) in a refinery within the southwest of Iran utilizing SQRA methodology. Front Public Health. (2022) 10:978354. doi: 10.3389/fpubh.2022.978354

PubMed Abstract | Crossref Full Text | Google Scholar

43. Khajeh Hoseini, L, Jalilzadeh Yengejeh, R, Mahmoudie, A, Mohammadi Rouzbehani, M, and Sabz Alipour, S. Prioritization of efficient strategic parameters within the removing of VOCs from the ROP system by utilizing AHP: a case examine of Abadan oil refinery. J Health Sci Surveill Syst. (2021) 9:199–205. doi: 10.30476/jhsss.2021.90008.1175

Crossref Full Text | Google Scholar

44. Morgan, S, Stewart, M, and Bennett, T. Simplifying COSHH and enhancing chemical security. Process Saf. Environ. Prot. (2020) 137:66–72. doi: 10.1016/j.psep.2019.12.027

Crossref Full Text | Google Scholar